利元亨高速高精3C领域激光专机系列:极片刻槽机、极片清洗机、隔膜切割机与智能焊接机

发布时间:2024-11-19 00:47分类: 无 浏览:505评论:0

近年来,5G、物联网、AI技术的融合推动了3C产品向更智能、高效、便捷发展,预计至2026年,全球3C电子市场将达19,762亿美元,年均增长5.8%。为应对消费者对高性能、长续航、轻便设备的需求,锂电池尤其在智能手机、笔记本电脑等快速迭代产品中发挥关键作用。激光智能加工技术因高效、精准、成本低等优势,在锂电池制造中广泛应用于极片处理、隔膜切割、焊接等环节,促进3C产业升级。但规模化应用下,激光加工面临边界效应挑战,如材料缺陷控制、微米级加工要求及实时调控技术需进一步突破。

为积极推动行业激光应用技术发展,利元亨旗下全资子公司广东舜元激光科技有限公司(简称舜元激光)基于极限制造理念结合市场需求,以提质、增效、降本和快速交付为目标,逐步拆解客户产品工艺指标,从定制化激光器-光束质量-光路稳定性-光斑尺寸-能量密度-焊接/切割工艺-位置检测-焊中-焊后检测-智能控制系统-结构稳定性出发形成了系列机理、标准及数据库。在此基础上积极推出激光极片刻槽机、激光极片清洗机、激光隔膜切割机、激光智能焊接机等产品。未来,在3C电池激光智能加工领域将会逐步推出数智一体化装备,不断引领激光智能加工技术革新。

舜元激光极片刻槽机采用飞行加工技术对电极进行织构处理,结合视觉定位及位置实时插补技术确保了飞行加工的一致性和高效性。设备支持定制分光提速方案,走带速度可达1000mm/s,线深精度为±4μm,优良率达到99.9%,产能达35PPM。设备兼容多种宽度的电极片,满足不同线深、线宽及线间距的工艺需求。激光飞行技术与位置实时插补技术的融合应用,凸显出激光极片刻槽设备的高效性和灵活性。

舜元激光极片清洗机主要用于电芯极片极耳焊接区域的涂层清理。设备通过连续走带方式对极片进行放卷和收卷,经过纠偏和定位,快速气化指定涂膜区域的活性物质。支持多种激光配置方案,并提供定制配置服务。极耳槽位长度和宽度精度可达±0.3mm,槽位间距和定位距精度达到±0.8mm。清洗效果显著,确保焊接区域的清洁度。设备的高效清洗能力和高精度控制,使其成为电池生产中的重要工具。

舜元激光隔膜切割机具备高速度、高精度、高稳定性及低成本等优势。最大切割速度5500mm/s,切割优率高达99.8%,稼动率97%,展现了卓越的高速性能。同时,设备集成高精度视觉定位、光斑定制、能量位置同步输出等技术,大幅度降低切割热影响及轨迹精度,热影响小于80μm,极大提升了产品的质量和一致性。设备支持多种幅宽的隔膜,以满足不同的工艺需求。此外,激光和CCD系统的尺寸反馈闭环调节功能,支持快速换型和双向纠偏,进一步确保了加工的高精度和可靠性。

舜元激光智能焊接机采用了视觉定位系统,实现快速准确的定位。设备集成MES系统和数字孪生技术,支持快速整线连通。支持铝极耳、铜极耳、镍极耳等多种材料的焊接,兼容焊接过程检测和多种激光配置方案。设备优良率达到99.5%,单激光器产能达30PPM。通过全自动工作流程设计和回流治具的应用,设备能迅速高效地完成换料过程,进一步提升整体生产效率。

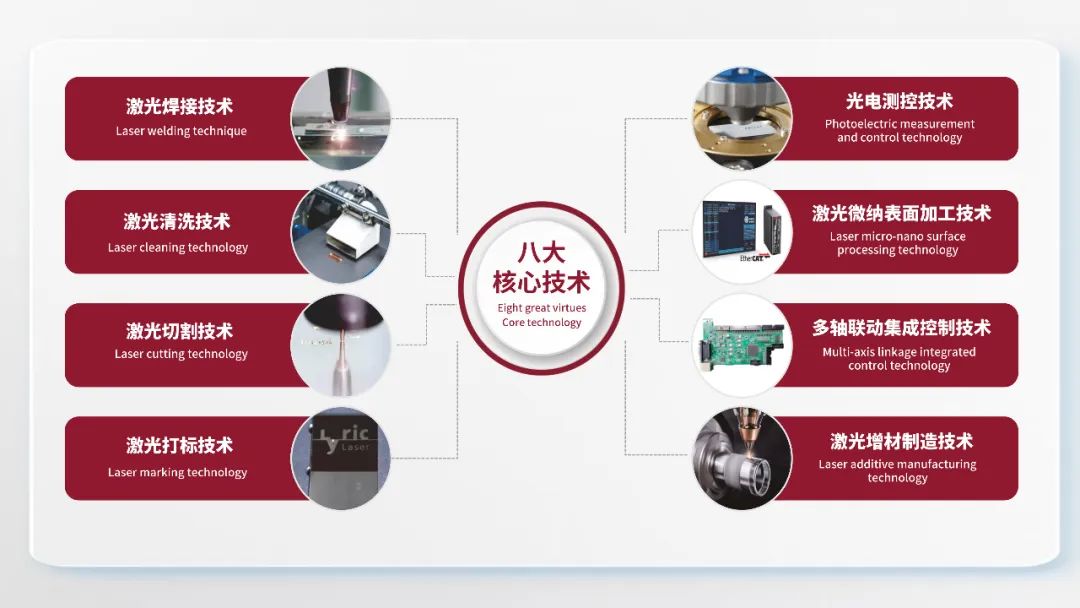

舜元激光设备的八大核心技术涵盖:激光焊接技术,实现高精度、高速度的焊接,适用于多种材料,确保高强度与美观;激光清洗技术,高效去除表面杂质,环保无污染;激光切割技术,提供精准快速的切割,边缘光滑;激光打标技术,形成高清晰度的永久性标记,适用于产品追溯和品牌标识;光电测控技术,实时监测与控制加工过程,提升质量与效率;激光微纳表面加工技术,实现微米至纳米级表面改性,适用于高性能器件制造;多轴联动集成控制技术,精确加工复杂三维曲面,提高灵活性;激光增材制造技术,直接制造复杂结构件,适合原型制作与个性化生产。这些技术共同构建了舜元激光的核心竞争力。

舜元激光以客户需求为导向,创新驱动,不断突破。我们的3C类电池解决方案涵盖激光加工工艺研发、位置精度控制、激光焊接工艺及焊接工艺优化等关键技术,打造了一系列高性能核心专机。未来,我们将继续探索激光技术的极限,开发更多适用于新能源产业的先进设备,提供高品质、高效率、高可靠性的解决方案,助力新能源产业的智能制造,为全球客户带来更优质的产品和服务。

Lyric High-Speed, High-Precision Laser Machines for the 3C Industry:

Pole Slotting Machine, Pole Sheet Cleaning Machine, Diaphragm Cutting Machine, and Intelligent Welding Machine

Current Development Status of the 3C Industry

In recent years, the integration of 5G, Internet of Things (IoT), and AI technologies has driven the 3C industry towards smarter, more efficient, and user-friendly products. It is projected that by 2026, the global 3C electronics market will reach $1,976.2 billion, with an average annual growth rate of 5.8%. In response to consumer demand for high-performance, long-lasting, and lightweight devices, lithium batteries have become especially crucial for rapidly iterating products, such as smartphones and laptops.

Laser intelligent processing technology, known for its high efficiency, precision, and low cost, has been widely applied in lithium battery manufacturing, including pole sheet processing, diaphragm cutting, and welding, thereby facilitating the upgrading of the 3C industry. However, with large-scale applications, laser processing faces challenges related to boundary effects, such as material defect control, micron-level processing requirements, and the need for advancements in real-time regulation technology.

To actively promote the advancement of laser application technology within the industry, Guangdong Shunyuan Laser Technology Co., Ltd. (Shunyuan Laser), a wholly owned subsidiary of Lyric, has developed a series of mechanisms, standards, and databases rooted in the concept of extreme manufacturing and aligned with market demand. With objectives of quality enhancement, efficiency improvement, cost reduction, and rapid delivery, Shunyuan Laser systematically deconstructs customer product process requirements, from customized lasers to beam quality, optical path stability, spot size, energy density, welding/cutting processes, position detection, in-process and post-welding inspection, intelligent control systems, and structural stability.

Building on this foundation, Shunyuan Laser has launched products such as the laser pole slotting machine, laser pole sheet cleaning machine, laser diaphragm cutting machine, and laser intelligent welding machine. In the future, Shunyuan Laser plans to introduce integrated digital-intelligent equipment in the field of 3C battery laser intelligent processing, continuously driving innovation in laser intelligent processing technology.

01 Laser Pole Slotting Machine

The Shunyuan Laser Pole Slotting Machine employs flight processing technology for texturing electrode surfaces and integrates visual positioning and real-time position interpolation technologies to ensure high consistency and efficiency in flight processing. The equipment supports customized beam splitting and speed enhancement options, achieving a belt speed of up to 1000 mm/s, with line depth accuracy of ±4 μm, an excellent yield rate of 99.9%, and a production capacity of 35 PPM. The machine is compatible with electrodes of various widths, meeting diverse requirements for line depth, width, and spacing. The integration of laser flight technology with real-time position interpolation underscores the high efficiency and flexibility of this laser pole slotting equipment.

02 Laser Electrode Sheet Cleaning Machine

The Shunyuan Laser Electrode Sheet Cleaning Machine is primarily used for removing coatings in the electrode tab welding area of battery cells. The equipment unwinds and rewinds the electrode sheet in a continuous strip process, performing correction and positioning before rapidly vaporizing the active material in the specified coated area. It supports multiple laser configuration options and offers customized configuration services. The precision of tab slot length and width can reach ±0.3 mm, with slot spacing and positioning accuracy up to ±0.8 mm. The cleaning effect is highly effective, ensuring cleanliness in the welding area. With its high-efficiency cleaning capability and precise control, this equipment is a vital tool in battery production.

03Laser Diaphragm Cutting Machine

The Shunyuan Laser Diaphragm Cutting Machine offers advantages of high speed, precision, stability, and cost efficiency. With a maximum cutting speed of 5500 mm/s, a high cutting yield rate of 99.8%, and an equipment utilization rate of 97%, it demonstrates exceptional high-speed performance. The machine integrates advanced technologies such as high-precision visual positioning, custom spot sizing, and synchronous energy position output, significantly reducing thermal impact on cutting and enhancing track accuracy, with thermal impact controlled to less than 80 μm. This greatly improves product quality and consistency. The equipment is compatible with various diaphragm widths to meet diverse process requirements. Additionally, the closed-loop dimensional feedback adjustment function of the laser and CCD system allows for rapid model changeover and bidirectional correction, further ensuring high precision and reliability in machining.

04 Laser Intelligent Welding Machine

The Shunyuan Laser Intelligent Welding Machine features a visual positioning system for fast and precise alignment. It integrates with an MES system and digital twin technology to enable rapid, full-line connectivity. The machine supports welding of various materials, including aluminum, copper, and nickel tabs, and is compatible with in-process welding inspection and multiple laser configuration options. The equipment achieves an excellent rate of 99.5%, with a production capacity of 30 PPM per laser. With a fully automated workflow and the application of reflux fixtures, the machine enables quick and efficient material changeover, further enhancing overall production efficiency.

Shunyuan Laser's Eight Core Technologies

Shunyuan Laser’s equipment incorporates eight core technologies: Laser Welding Technology – Enables high-precision, high-speed welding for various materials, ensuring both strength and aesthetic quality; Laser Cleaning Technology – Efficiently removes surface impurities in an environmentally friendly, pollution-free manner; Laser Cutting Technology – Provides precise, rapid cutting with smooth edges; Laser Marking Technology – Creates high-definition, permanent markings suitable for product traceability and brand identification; Photoelectric Measurement and Control Technology – Real-time monitoring and control of the processing workflow, enhancing quality and efficiency; Laser Micro-Nano Surface Processing Technology – Achieves micron to nano-level surface modifications, ideal for high-performance device manufacturing; Multi-Axis Linkage Integrated Control Technology – Precisely processes complex three-dimensional surfaces, improving processing flexibility; Laser Additive Manufacturing Technology – Enables the direct manufacturing of complex structural components, ideal for prototyping and customized production. These technologies together build the core competitiveness of Shunyuan laser.

Shunyuan Laser is customer-driven and innovation-focused, constantly pushing boundaries. Our 3C battery solutions encompass key technologies, including laser processing development, position accuracy control, laser welding, and welding process optimization, resulting in a range of high-performance, specialized equipment. Looking forward, we will continue to explore the limits of laser technology, developing advanced equipment for the new energy sector. Our commitment is to provide high-quality, efficient, and reliable solutions that support intelligent manufacturing in the new energy industry, delivering superior products and services to customers worldwide.

相关文章

- 排行