【编辑推荐】2024年5期技术交流

发布时间:2024-12-14 06:32分类: 无 浏览:458评论:0

1

技术交流

姚代兵1,高哲1,常海涛2,路密1∗

(1. 厦门理工学院材料科学与工程学院,福建 厦门 361024;

2. 福建南平南孚电池有限公司,福建省高效能电池重点实验室,福建 南平 353000)

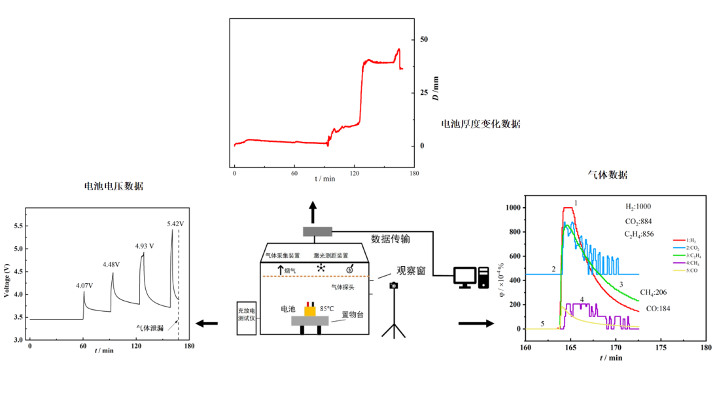

摘要:研究极端条件下的多场耦合相互作用,对深入理解锂离子电池的热失控机理非常重要。本文作者在多场耦合电池安全性测试系统(JY-MFS-80L)中,以1380200-20 Ah软包磷酸铁锂(LiFePO4)锂离子电池为研究对象,将其在85 ℃的过热环境下阶梯式增加过充电电压至5.42 V,发现电池发生气体泄压但未出现起火或爆炸,表明该电池即使在过热条件下也具有较强的耐过充电能力。泄压过程中首先检测到氢气的信号,随后检测到一氧化碳、烷烃和烯烃等易燃气体,易燃气体增加了电池出现爆炸甚至闪爆的风险。XRD测试表明,过充电后正极活性物质LiFePO4完全去锂化生成了磷酸铁(FePO4),SEM显示部分过充电后的FePO4颗粒出现了裂纹,但结构未进一步被破坏,证实了LiFePO4的高热稳定性。

Tolerance to overcharge of lithium iron phosphate Li-ion batteryunder overheating

YAO Daibing1,GAO Zhe1,CHANG Haitao2,LU Mi1∗

(1. School of Materials Science and Engineering,Xiamen University of Technology,Xiamen,Fujian 361024,China;2. Fujian Nanping Nanfu Battery Co.,Ltd., Fujian Key Laboratory of High Performance Battery,Nanping,Fujian 353000,China)

Abstract: Studying the multi-field coupling interaction under extreme conditions is very important for understanding the thermal runaway mechanism of Li-ion battery. In the multi-field coupling battery safety test system (JY-MFS-80L), the 1380200-20 Ah pouch lithium iron phosphate(LiFePO4) Li-ion battery is taken as the research object, the overcharge voltage is increased to 5.42 V step by step in the overheated environment at 85 °C. It is found that the battery has gas pressure relief but no fire or explosion, indicating that the battery has strong overcharge resistance even under overheated conditions. The hydrogen is detected firstly and followed by the signals of flammable gas such as carbon monoxide, alkane and olefin etc. The flammable gas increases the risk of battery explosion or even flash explosion. XRD test shows that the cathode active material LiFePO4 is fully delithiated to form FePO4. The SEM test shows that some cracks on the surface of FePO4 particles but the structure is not further destructed, indicating the high thermal stability of LiFePO4.

图1 实验中重要图片

Fig.1 Important pictures in the experiment

引用格式

姚代兵,高哲,常海涛,等. 过热下磷酸铁锂锂离子电池的过充电耐受性[J]. 电池,2024,54(5):660-663.

YAO D B,GAO Z,CHANG H T,et al. Tolerance to overcharge of lithium iron phosphate Li-ion battery under overheating[J]. Dianchi(Battery Bimonthly),2024,54(5):660-663.(点此下载文章全文)

张海龙1,2,3∗,张存满1,2,汪飞杰1,2,张靖1,2

(1. 同济大学新能源汽车工程中心,上海 201804;

2. 同济大学汽车学院,上海 201804;

3. 上海清能合睿兹新能源科技有限公司,上海 200444)

摘要:质子交换膜燃料电池(PEMFC)作为一项清洁能源技术,以高效、环保的特点,成为实现零碳排放目标的关键技术之一。探讨兆瓦级PEMFC系统的工程应用,特别是在氯碱工业中的商业化潜力。通过分析系统各关键组件如逆变器、变压器、板式换热器以及能量管理系统的选型标准,为PEMFC系统的设计提供理论指导。在PEMFC系统运行过程中,空压机和散热风扇是自耗电的主要来源,二者分别占据自耗电总功率的约82.0%和10.7%。优化这些部件的工作效率对于提升整个系统的能效至关重要。将PEMFC技术引入氯碱工厂,不仅能够较好利用以往直接排放的氢气资源,还能显著提高工厂的能量使用效率,从而为企业带来经济效益。

Design and applications of megawatt-scale PEMFC system

ZHANG Hailong1,2,3∗,ZHANG Cunman1,2,WANG Feijie1,2,ZHANG Jing1,2

(1. Clean Energy Automotive Engineering Center,Tongji University,Shanghai 201804,China;

2. School of Automotive Studies,Tongji University,Shanghai 201804,China;

3. Shanghai Qingneng Horizon New Energy Technology Co.,Ltd.,Shanghai 200444,China)

Abstract:As a clean energy technology, proton exchange membrane fuel cell (PEMFC) has become one of the key technologies to achieve zero carbon emission targets due to its high efficiency and environmental friendliness. The engineering applications of megawatt-level PEMFC systems are discussed, particularly focusing on commercial potential within the chlor-alkali industry. By analyzing the selection criteria for key components such as inverters, transformers, plate heat exchangers and energy management systems, theoretical guidance is provided for the design of PEMFC systems. The air compressor and cooling fans are the primary sources of self-consumption power within the PEMFC system, accounting for approximately 82.0% and 10.7% of the total self-consumed power, respectively. Optimizing the operational efficiency of these components is critical to enhancing the overall system's performance. Introducing PEMFC technology into chlor-alkali plants can not only make better use of hydrogen resources directly discharged in the past, but also significantly improve the energy efficiency of the plant, thus bringing economic benefits to the enterprise.

图1 兆瓦级PEMFC系统布置示意图

Fig.1 Schematic diagram of the megawatt PEMFC system layout

引用格式

张海龙,张存满,汪飞杰,等. 兆瓦级PEMFC系统的设计和应用[J]. 电池,2024,54(5):664-667.

ZHANG H L,ZHANG C M,WANG F J,et al. Design and applications of megawatt-scale PEMFC system[J] . Dianchi(Battery Bimonthly),2024,54(5):664-667.(点此下载文章全文)

赵家义∗,许庆顺

(宁德时代新能源科技股份有限公司,福建 宁德 352100)

摘要:在锂离子电池的使用和运输过程中,碰撞难以避免。鉴于其高能量密度,品质把控至关重要。物理撞击可能致使电池内部短路,引发发热、冒烟甚至起火等高危风险。为检验成品电池的综合品质,以典型的18650型锂离子电池为例,进行出厂前的撞击实验,以评估电池的可靠性。介绍八角转鼓设备的机械结构,探讨撞击锂离子电池的测试机理,并依据相关国家标准制定详细测试方法。通过运动仿真模拟,确定锂离子电池在平均撞击加速度下八角转鼓设备所需的转速,采用不同仿真参数设置进行运动分析,并选取最优参数作为测试条件。收集测试后锂离子电池的内阻及容量数据,当八角转鼓设备转动速度在100~121 r/min时,通过图表分析可知,锂离子电池的交流内阻均值呈现变大趋势,容量均值则出现变小趋势。另外,利用所收集数据运用六西格玛(6σ)工程方法判断某批次锂离子电池的出厂品质是否满足要求。完善消费类锂离子电池日常使用撞击测试方法,为提升新能源行业中锂离子电池的安全测试提出课题。

Research on impact test methods and parameters of Li-ion battery

ZHAO Jiayi∗,XU Qingshun

(Contemporary Amperex Technology Co.,Ltd.,Ningde,Fujian 352100,China)

Abstract: In the process of using and transporting Li-ion battery, collisions are hard to avoid. Given its high energy density, quality control is of crucial importance. Physical impacts may cause internal short circuits in the battery, leading to high-risk situations such as heating, smoking and even fire. To test the comprehensive quality of finished batteries, the typical 18650 type Li-ion battery is taken as an example, an impact test before leaving the factory to evaluate the battery reliability is conducted. The mechanical structure of the octagonal-drum equipment is introduced, the test mechanism of impacting Li-ion battery is discussed, the detailed test methods are according to relevant national standards. Through motion simulation, the speed required for the octagonal-drum equipment of the Li-ion battery under the average impact acceleration is determined. Different simulation parameter settings are used for motion analysis, the optimal parameters are selected as test conditions. After the test, the internal resistance and capacity data of Li-ion battery are collected. When the rotational speed of the octagonal-drum equipment is in the range of 100-121 r/min, through chart analysis, the average value of the alternating current internal resistance of Li-ion battery shows an increasing trend, while the average value of capacity shows a decreasing trend. In addition, the collected data are analyzed by the six sigma (6σ) engineering method to judge whether the factory quality of a certain batch of Li-ion battery meets the requirements. The impact test method for consumer Li-ion battery in daily use are improved and a topic for improving the safety test of Li-ion battery in the new energy industry is proposed.

引用格式

赵家义,许庆顺. 锂离子电池撞击测试方法及参数研究[J]. 电池,2024,54(5):668-671.

ZHAO J Y,XU Q S. Research on impact test methods and parameters of Li-ion battery[J]. Dianchi(Battery Bimonthly),2024,54(5):668-671.(点此下载文章全文)

陶鑫,谢松∗

(中国民用航空飞行学院民航安全工程学院,四川 德阳 618307)

摘要:钛酸锂(Li4Ti5O12)负极锂离子电池因具有倍率性能好、循环寿命长、安全性高等优势而备受关注,然而,近年来仍然发生了相关热失控的事故。为了深入探究倍率对电池热安全性的影响,本文作者以圆柱形LiNi0.5Co0.2Mn0.3O2/Li4Ti5O12锂离子电池为研究对象,通过不同充放电倍率循环及热失控实验,分析了电池在不同倍率循环条件下的容量-电压、放电直流内阻和热失控温度变化等数据。结果表明,高倍率循环会导致电池正极活性物质的损失,进而引起循环性能和热安全性能的衰减。电池热安全性与倍率呈现出明显的负相关关系。随着倍率由2.00 C升至8.00 C,电池的热失控触发温度由358.5 ℃降低至254.1 ℃,同时热失控时间由3 608 s缩短到2 980 s,热失控时的最大升温速率由34.2 ℃/s增加至59.7 ℃/s。研究结果对于提高钛酸锂负极锂离子电池的安全性能,优化电池设计和运行策略提供一定的参考。

Effect of rate on the thermal safety of lithium titanate

anode Li-ion battery

TAO Xin,XIE Song∗

(College of Civil Aviation Safety Engineering,Civil Aviation Flight University of China,Deyang,Sichuan 618307,China)

Abstract: Lithium titanate (Li4Ti5O12) anode Li-ion battery has attracted attention due to the advantages such as good rate capability, long cycle life and high safety. However, in recent years, accidents related to thermal runaway have still occurred. To investigate the impact of charge/discharge rates on the thermal safety of batteries, cylindrical LiNi0.5Co0.2Mn0.3O2/Li4Ti5O12 Li-ion battery is taken as the research object. Through cycling experiments at varying charge/discharge rates and thermal runaway tests, data on capacity-voltage relationships, discharge DC internal resistance and thermal runaway temperatures under different cycling conditions are analyzed. The research findings indicate that high-rate cycling leads to the loss of active materials in the battery cathode, resulting in the deterioration of both cycling performance and thermal safety. There is a clear negative correlation between battery thermal safety and the charge/discharge rate. As the charge/discharge rate increases from 2.00 C to 8.00 C, the triggering temperature for thermal runaway in the battery decreases from 358.5 ℃ to 254.1 ℃. Simultaneously, the duration of thermal runaway reduces from 3 608 s to 2 980 s, the maximum temperature rise rate during thermal runaway increases from 34.2 ℃/s to 59.7 ℃/s. The research results provide a certain reference for enhancing the safety performance of lithium titanate anode Li-ion battery, as well as for optimizing battery design and operational strategies.

引用格式

陶鑫,谢松. 倍率对钛酸锂负极锂离子电池热安全的影响[J]. 电池,2024,54(5):672-676.

TAO X,XIE S. Effect of rate on the thermal safety of lithium titanate anode Li-ion battery [J] . Dianchi ( Battery Bimonthly),2024,54(5):672-676.(点此下载文章全文)

田文燕∗,胡洪瑞,刘富亮,刘江涛,石斌

(贵州梅岭电源有限公司,特种化学电源全国重点实验室,贵州 遵义 563003)

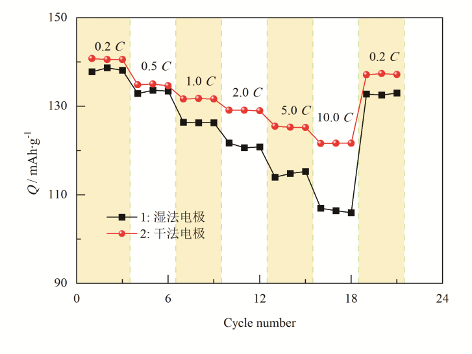

摘要:采用干法电极工艺制备LiCoO2干法电极,通过SEM、X射线能谱仪、电阻率测试仪、电化学阻抗(EIS)、恒流充放电等方法对比干法电极和传统湿法电极在微观形貌、导电性、倍率性能和循环等性能的差异。纤维化的聚四氟乙烯(PTFE)广泛、均匀地分布在LiCoO2活性物质颗粒的周围,在干法电极内部形成了一个完整、致密的三维网状结构。与LiCoO2湿法电极相比,干法电极膜表面有着更加平整的形貌,活性物质与导电剂之间接触更为紧密;通过极片电阻率测试可知,干法电极的极片电阻率(为4.31 Ω•cm)低于湿法正极的(6.03 Ω•cm),表明干法电极活性材料颗粒之间以及与导电剂颗粒的接触更紧密,电极的导电性更好;同时,EIS测试结果也证明干法电极比传统湿法电极具有更小的电荷转移电阻和扩散电阻;以1.0 C在2.5~4.2 V循环200次,容量保持率为80.28%,优于湿法电极(72.85%),表明由纤维状的PTFE形成的三维网络结构能够提升材料之间的导电性,并防止活性物质颗粒在循环过程中从集流体表面脱落,提升了电池的倍率和循环稳定性。

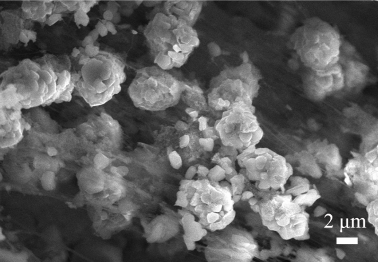

Electrochemical performance of LiCoO2

electrode prepared by dry method

TIAN Wenyan∗,HU Hongrui,LIU Fuliang,LIU Jiangtao,SHI Bin

(State Key Laboratory of Advanced Chemical Power Sources,Guizhou Meiling Power Sources Co.,Ltd.,Zunyi,Guizhou 563003,China)

Abstract: LiCoO2 dry electrodes are prepared by the dry electrode process, the differences between the dry electrodes and the traditional wet electrodes in terms of microscopic morphology, electrical conductivity, rate capability and cycle performance are comparatively investigated using SEM, X-ray energy spectrometry, resistivity tester, electrochemical impedance spectroscopy and galvanostatic charging/discharging. In the dry electrodes, the fibrillated polytetrafluoroethylene (PTFE) is widely and uniformly distributed around the LiCoO2 active substance particles, forming a complete and dense three-dimensional network structure. Compared with the LiCoO2 wet electrode, the membrane surface of the dry electrode has a flatter morphology, the contact between the active material and the conductive agent is more compact. It can be seen from the electrode resistivity test that the dry electrode has a lower electrode resistivity (4.31 Ω•cm) than that of the wet anode (6.03 Ω•cm), which indicates that the contact between the active material particles of the dry electrode and the conductive agent particles is more compact, the conductivity of the electrode is better. At the same time, the results of EIS test prove that the dry electrode has smaller charge transfer resistance and diffusion resistance than the traditional wet electrode. After 200 cycles at 1.0 C in 2.5-4.2 V, the dry electrodes delivered a capacity retention of 80.28%, which is better than that of the wet electrode (72.85%). It indicates that the three-dimensional network structure formed by fibrous PTFE can improve the electrical conductivity between the materials and prevent the active substance particles from dislodging from the surface of the collector during the cycling process, which improves rate capability and cycle stability of the battery.

图1 LiCoO2干法电极的截面SEM图

Fig.1 SEM cross-sections of LiCoO2 dry electrode

图2 LiCoO2湿法电极和干法电极组装的扣式电池的倍率性能

Fig.2 Rate capability of button cells assembled with LiCoO2 wet and dry electrodes

引用格式

田文燕,胡洪瑞,刘富亮,等. 干法制备LiCoO2电极的电化学性能[J]. 电池,2024,54(5):677-681.

TIAN W Y,HU H R,LIU F L,et al. Electrochemical performance of LiCoO2 electrode prepared by dry method[J].Dianchi(Battery Bimonthly),2024,54(5):677-681.(点此下载文章全文)

张越超∗,高金津,高秀玲,马华

(天津市捷威动力工业有限公司,天津 300380)

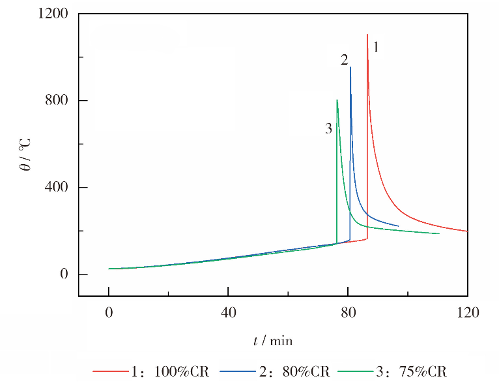

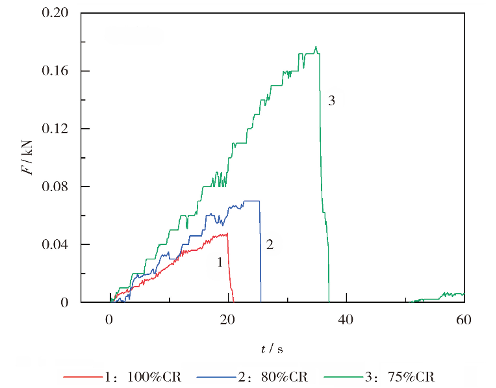

摘要:高比能量动力锂离子电池及安全性一直是研究的重点。以高镍三元材料LiNi0.8Co0.1Mn0.1O2(NCM811)为正极、石墨复合硅氧材料为负极,制备了300 W·h/kg的动力锂离子电池。为得到的电池性能更接近实际应用场景,以模组循环的方式对电池进行老化,评价电池从制成到循环衰减至容量保持率为75%时的全周期安全性变化。通过电池加热测试评价电池的热稳定性变化,通过针刺测试评价内短路耐受性的变化,并通过差示扫描量热(DSC)、SEM、四探针测试分析电池安全性能变化的机制。电池在容量保持率100%(循环前)、80%和75%时的热失控温度分别为167 ℃、161 ℃和143 ℃,针刺热失控深度分别为1.99 mm、2.52 mm和3.54 mm。随着循环的进行,硅氧负极的固体电解质相界面(SEI)膜持续大幅增加,导致热稳定性下降,内短路耐受性提高。电解液的不断减少,导致电池生命后期的热失控放热量下降。研究揭示了高镍-石墨/硅氧体系的全周期安全特性和变化规律,有助于提前识别电池设计、制造和应用管理中的关键点和风险点,完善设计和管理方案。

The full cycle safety of high specific energy Li-ion battery

ZHANG Yuechao∗,GAO Jinjin,GAO Xiuling,MA Hua

(Tianjin EV Energies Co.,Ltd.,Tianjin 300380,China)

Abstract: Li-ion battery with high specific energy and the safety have always been a focus of research. A 300 W·h/kg power Li-ion battery is prepared using high-nickel ternary materials LiNi0.8Co0.1Mn0.1O2 (NCM811) as the cathode and graphite-SiOx material as the anode. In order to simulate the practical application conditions, the battery is aged by module cycling, the full cycle safety changes of the batteries are analyzed from production to cyclic decay to the capacity retention (CR) of 75%. The change in thermal stability of the battery is evaluated by heating tests, the changes in internal short circuit tolerance are evaluated by nail penetration tests. The mechanism of battery safety performance changes is analyzed by differential scanning calorimeter (DSC), SEM and four-probe testing. The thermal runaway temperatures of the batteries at 100% (before cycling), 80% and 75% capacity retention are 167 ℃, 161 ℃ and 143 ℃, respectively. The penetration depths while thermal runaway are 1.99 mm, 2.52 mm and 3.54 mm, respectively. As the cycles continue, the solid electrolyte interphase (SEI) film on the SiOx anode continues to increases significantly, leading to a decrease in the thermal stability and an improvement in its internal short-circuit tolerance. The reduction of electrolytes leads to the decrease of thermal runaway heat release in the later stage of battery life. The study reveals the safety changes and changing patterns of the nickel-rich/graphite-SiOx system, which helps to identify key and risk points in battery design, manufacturing and application management in advance, and improve the design and management plan.

图1 不同CR电池的加热曲线

Fig.1 Heating curves of batteries at different capacity retention(CR)

图2 不同CR电池的针刺耐受程度

Fig.2 Nail penetration tolerance of batteries at different CR

引用格式

张越超,高金津,高秀玲,等. 高比能量锂离子电池的全周期安全性[J]. 电池,2024,54(5):682-687.

ZHANG Y C,GAO J J,GAO X L,et al. The full cycle safety of high specific energy Li-ion battery[J]. Dianchi( Battery Bimonthly),2024,54(5):682-687.(点此下载文章全文)

朱冰1∗,夏天2

(1. 上海电子信息职业技术学院通信与信息工程学院,上海市 201411;

2. 上海第二工业大学计算机与信息工程学院,上海市 201209)

摘要:锂离子电池作为现代能源存储领域中不可或缺的组件,以高能量密度、长寿命和质量轻的优势得到广泛应用。然而,电池的荷电状态(SOC)和健康状态(SOH)的准确估算仍然是电池管理中的一大难题,尤其是在电池使用过程中会受到外界环境、使用频率等多种因素的影响。目前常用的估算方法包括开路电压法、安时积分法、扩展卡尔曼滤波(EKF)和粒子滤波(PF)等,但这些传统方法存在估算误差较大、计算量高且无法实时准确跟踪电池状态等问题。为了解决这些挑战,本文作者引入一种基于多元宇宙优化(MVO)算法的方法,对SOC和SOH进行估算。该方法结合实验设计,通过等效电路模型进行多次迭代计算,实现了对电池状态的精确跟踪和管理。结果表明,MVO算法相比传统方法具有显著优势,模型拟合度达到95.3%,并在14次迭代后实现SOC估算的稳定性。此外,SOH估算的稳定性提升了119%,计算空间需求减少了78%。研究展示了MVO算法在锂离子电池管理中的巨大潜力,并为未来高效的能源管理系统提供了强有力的技术支持。

Estimation of SOC and SOH for Li-ion battery by multiverse optimization

ZHU Bing1∗,XIA Tian2

(1. College of Communication and Information Engineering,Shanghai Technical Institute of Electronics & Information,Shanghai 201411,China; 2. School of Computer and Information Engineering,Shanghai Polytechnic University,Shanghai 201209,China)

Abstract: Li-ion battery, as an indispensable component in the field of modern energy storage, is widely used due to their high energy density, long life and light weight. However, accurately estimating the state of charge (SOC) and state of health (SOH) remains a significant challenge, particularly because these parameters are affected by external conditions and usage patterns. Traditional estimation methods, such as open-circuit voltage (OCV), amper-hour integral, extended Kalman filter (EKF) and particle filter (PF) methods, often suffer from large estimation errors, high computational demands and difficulty in real-time monitoring. To address these challenges, a novel approach using the multi-verse optimization (MVO) algorithm for estimating SOC and SOH is introduced. The method integrates experimental design and iteratively calculates battery states based on an equivalent circuit model, enabling precise tracking and management of the battery's condition. The results show that the MVO algorithm offers significant advantages over traditional methods, achieving a model fit of 95.3% and stabilizing SOC estimation after 14 iterations. Additionally, SOH estimation stability is improved by 119%, while computational space is reduced by 78%. The research highlights the potential of the MVO algorithm in Li-ion battery management and provides a strong foundation for future energy management systems that prioritize efficiency and accuracy.

引用格式

朱冰,夏天. 多元宇宙优化估算锂离子电池的SOC 与SOH[J]. 电池,2024,54(5):688-692.

ZHU B, XIA T. Estimation of SOC and SOH for Li-ion battery by multi-verse optimization [J] . Dianchi ( Battery Bimonthly),2024,54(5):688-692.(点此下载文章全文)

戚红月1∗,董炎军2,张巡蒙1,苑景春1,陈绍林1,张育红3

(1. 杭州华宇新能源研究院有限公司,浙江 杭州 311300;

2. 浙江华宇钠电新能源科技有限公司,浙江 杭州 311300;

3. 浙江南都电源动力股份有限公司,浙江 杭州 310012)

摘要:随着人们对两轮电动车需求的日益增长以及对电池安全要求的日益重视,铅酸蓄电池以更高的安全性、优质的循环性能以及优越的价格,越来越受到消费者的青睐。本文作者通过优化电池板栅结构,延长电动自行车用铅酸电池的寿命,对电动自行车用铅酸电池的板栅进行研究。

通过解剖失效电池并对板栅进行分析,发现板栅靠近极耳的区域筋条腐蚀严重,而靠近底部的筋条基本完好。在此分析基础上,优化板栅网格布局以均匀板栅电位,优化板栅截面以加强重点腐蚀区域的强度,从而实现增加板栅耐腐蚀时间,达到延长电池寿命的目的。

通过对板栅建模分析以及实际产品测试,改进后电池的循环次数从428次增加至633次,约是改进前的1.5倍。实验对长寿命电动自行车铅酸电池的开发具有一定的引导作用。

Improvement for structure of lead-acid battery positive grid

QI Hongyue1∗,DONG Yanjun2,ZHANG Xunmeng1,YUAN Jingchun1,CHEN Shaolin1,ZHANG Yuhong3

(1. Hangzhou Huayu New Energy Research Institute Co.,Ltd.,Hangzhou,Zhejiang 311300,China; 2. Zhejiang Huayu Sodium Battery New Energy Technology Co.,Ltd.,Hangzhou,Zhejiang 311300,China;3. Zhejiang Narada Power Source Co.,Ltd.,Hangzhou,Zhejiang 310012,China)

Abstract:With the increasing demand for two-wheeled electric vehicles and the growing emphasis on battery safety requirements, lead-acid battery is increasingly favored by consumers for their higher safety, high-quality cycle performance, and superior price. The grid of the lead-acid battery used in electric bicycles is studied by optimizing the structure of the battery grid and extending the life of the lead-acid battery for electric bicycles.

引用格式

戚红月,董炎军,张巡蒙,等. 铅酸电池正极板栅结构的改进[J]. 电池,2024,54(5):693-695.

QI H Y,DONG Y J,ZHANG X M,et al. Improvement for structure of lead-acid battery positive grid[J]. Dianchi(Battery Bimonthly),2024,54(5):693-695.(点此下载文章全文)

苏宝定1∗,李波2,李永利2,邓炜2

(1. 中广核风电有限公司,北京 100071;

2. 北京市中保网盾科技有限公司,北京 102200)

摘要:本文作者结合数据驱动模型和经验模型,提出了一种组合估计模型。首先,以充电循环次数为周期,获得数据集中的电池表面温度、充电最高截止电压、充电最低截止电压、充电电流和充电容量等特征,训练长短期记忆网络(LSTM)模型,然后使用基于LSTM模型的数据驱动方式进行锂离子电池健康状态(SOH)的初步估计,再次将工况中提取到的特征通过LSTM模型估计得到在线估计值,并将该值用于拟合双指数经验模型,进一步使用工况中的观测值和在线估计值的误差和增益以更新双指数模型对应的参数,以此进行以循环周期为单位的迭代估计,从而实现更精确的SOH实时估计。结果表明,该组合估计模型能够准确估计锂离子电池的SOH,且当观测器的修正周期为单个循环周期时,估计结果的平均绝对误差(MAE)和均方根误差(RMSE)均值分别为0.003 3和0.004 2,优于单纯LSTM数据驱动下的SOH估计性能。

Li-ion battery SOH estimation based on

data-driven and hybrid model

SU Baoding1∗,LI Bo2,LI Yongli2,DENG Wei2

(1. CGN Wind & Power Co.,Ltd., Beijing 100071,China;

2. Beijing Zhongbao Wangdun Technology Co.,Ltd., Beijing 102200,China)

Abstract: A hybrid estimation model that combines data-driven and empirical models is proposed. Firstly, using the charging cycle count as a period, features such as battery surface temperature, maximum cutoff voltage during charging, minimum cutoff voltage during charging, charging current, and charging capacity are extracted from the dataset to train a long short-term memory (LSTM) model. The LSTM-based data-driven approach is then used for an initial estimation of the Li-ion battery's state of health (SOH). The features extracted under operating conditions are again estimated using the LSTM model to obtain online estimates. These online estimates are then used to fit a double exponential empirical model. Further, the error and gain between the observed values and the online estimates under operating conditions are used to update the parameters of the double exponential model. This process iterates on a per-cycle basis, leading to more accurate real-time SOH estimation. The results show that this hybrid estimation model can accurately estimate the SOH of Li-ion battery, with the average mean absolute error (MAE) and the average root mean square error (RMSE) of the estimation results being 0.003 3 and 0.004 2, respectively, when the correction cycle of the observer is a single cycle. Its performance is superior to the SOH estimation using only the LSTM data-driven approach.

引用格式

苏宝定,李波,李永利,等. 基于数据驱动与组合模型的锂离子电池SOH 估计[J]. 电池,2024,54(5):696-699.

SU B D,LI B,LI Y L,et al. Li-ion battery SOH estimation based on data-driven and hybrid model[J]. Dianchi( Battery Bimonthly),2024,54(5):696-699.(点此下载文章全文)

刘富亮1,2,付紫微1∗,陈安国1,张校刚2

(1. 贵州梅岭电源有限公司,特种化学电源全国重点实验室,贵州 遵义 563000;2. 南京航空航天大学材料科学与技术学院,江苏 南京 211106)

摘要:高功率电池型电容器是一种兼具高比能量和高比功率的储能器件。在高功率大电流脉冲放电条件下,极片的微观结构是影响电容器脉冲放电性能的主要影响因素。因此,对极片微观结构的要求较高:①主体材料与辅助材料的分散均匀性会影响导电剂在活性物质颗粒间导电网络和有效孔隙结构的构建,影响电子、离子的传输;②浆料的分散均匀性的稳定会影响极片的一致性、连续涂布的稳定性(电阻率、孔隙率、涂层负载量)和电容器的功率特性。其中,在搅拌工艺固定的条件下,固含量会对浆料的物性产生显著的影响。在干混捏合搅拌过程中,对浆料悬浮液稳定性、均一性及极片微观形貌影响较大的因素有搅拌速率、搅拌时间、固含量等参数。从适合工业生产的角度出发,目前市场上量产用搅拌设备的容积、搅拌桨数量和排布方式已经成熟,改变搅拌速率对浆料的性能不会产生明显影响;对搅拌时间而言,搅拌时间越长,浆料的稳定性和一致性越好,是行业内的共识,但从商业化角度出发,延长时间会增加生产成本,不利于工业生产。通过调整固含量来优化浆料的性质和极片的微观形貌,是行业内认为能够快速提升极片物理化学性能的手段之一,从控制生产成本、提高生产效率和工艺可行性方面而言,也具有广泛的应用前景。

Influence of slurry solid content on performance of battery-type capacitor

LIU Fuliang1,2,FU Ziwei1∗,CHEN Anguo1,ZHANG Xiaogang2

(1. State Key Laboratory of Advanced Chemical Power Sources,Guizhou Meiling Power Sources Co.,Ltd.,Zunyi,Guizhou 563000,China; 2. College of Materials Science and Technology,Nanjing University of Aeronauticsand Astronautics,Nanjing,Jiangsu 211106,China)

Abstract: High-power battery capacitors are energy storage devices that combine high specific energy and high specific power. Under the condition of high power and high current pulse discharge, the microstructure of the electrode is the main influencing factor on the pulse discharge performance of capacitors. Therefore, there are high requirements for the microstructure of the polarizer: 1) The dispersion uniformity of the main material and auxiliary materials affects the construction of the conductive network and effective pore structure of the conductive agent between the active material particles, and affects the transport of electrons and ions; 2) The stability of slurry dispersion uniformity affects the consistency of the polarizer, the stability of continuous coating (resistivity, porosity, coating load) and the power characteristics of the capacitor. Among them, under the fixed conditions of the stirring process, the solid content has a significant impact on the physical properties of the slurry. During the dry mixing, kneading and stirring process, factors that have a significant impact on the stability, uniformity and microstructure of the slurry suspension include stirring rate, stirring time and solid content. From the perspective of suitability for industrial production, the volume, number and arrangement of mixing equipment for mass production in the market have matured, and changing the mixing rate cannot have a significant impact on the performance of the slurry; For the mixing time, it is a consensus in the industry that the longer the mixing time, the better the stability and consistency of the slurry. However, from a commercial perspective, the extension of time increases production costs and is not conducive to industrial production. Adjusting the solid content to optimize the properties of the slurry and the microstructure of the polarizer is considered one of the methods in the industry that can quickly improve the physical and chemical performance of the polarizer. From the aspects of controlling production costs, improving production efficiency and process feasibility, it also has broad application prospects.

引用格式

刘富亮,付紫微,陈安国,等. 浆料固含量对电池型电容器性能的影响[J]. 电池,2024,54(5):700-705.

LIU F L,FU Z W,CHEN A G,et al. Influence of slurry solid content on performance of battery-type capacitor[J]. Dianchi(Battery Bimonthly),2024,54(5):700-705.(点此下载文章全文)

往期回顾

01

02

03

点击下方名片关注我们

扫码订阅

了解更多精彩内容

微信编辑 汤翊 责编 复审 刘冰 终审 李胜

本刊未委托任何第三方机构或个人代为收费或组稿,作者朋友们请投稿至唯一指定邮箱:dianchi@batterypub.com

-1971年创刊-欢迎转载传播-

- 排行